Need for Speed 10-05-2023

This week on Wednesday the Bristol and Bath Science Park hosted an event with F1 in Schools. F1 in Schools is a STEM organisation that challenges students to produce small-scale vehicles to race against other teams from across the globe to see who can produce the fastest vehicle.

We at Xor Systems have the opportunity to talk to some of the teams as they got ready to try their car on the race track, and we got some interesting insights into the processes required to design their race cars.

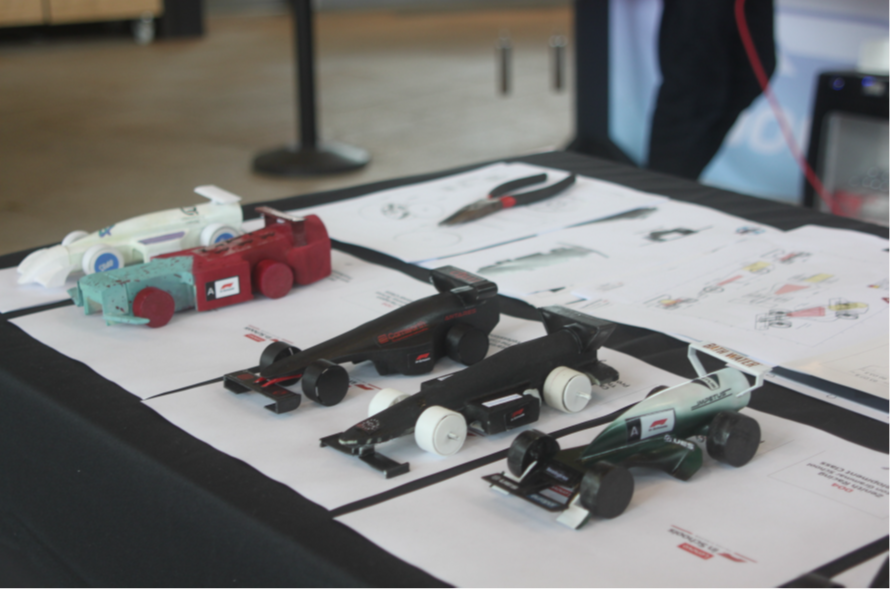

The image above shows the Scrutineering desk. All of the cars have to pass scrutineering before they can race and also the teams get scored against scrutineering rules. It makes the scheme much more realistic, because the students have to abide by rules and will lose points if they fail to match the rules.

We took the time to talk to some of the team and asked them about their thought process when designing the cars they made and the things that they focused on optimising in their designs.

The first team I talked to focused on the weight optimisation of their car. they tried to reduce the mass of the car as much as possible. in order to do this they pursued many avenues, one of which was the development and employment of forged carbon wheels, a step that drastically reduced the weight of the car and allowed greater acceleration.

The second team we spoke to decided to explore the use of aero-features to try to use turbulance-generating features to decrease drag by generating a layer of turbulent air. However, they found that these features and the aerodynamic effects that they are designed to produce didn't scale well with the small size of the vehicles in this competition.

The final team we talked to utilised additional 3D printed features to create aerodynamic surfaces too thin and fragile to be machined from the foam comprising the main body of the car.

The teams get judged on the displays they put together. It's a bit like a tradeshow, the stands are all branded, the teams wear branded clothing and the stands are artfully laid out. Most of the teams explained the work they had done, with technical drawings. The team members had different roles, such as Project manager, Aerodynamics etc.